Breathing clean air is essential to our overall health and well-being, and the same holds true for engines. The air filter in your Honda engine plays a critical role in keeping it running smoothly and efficiently, but not all air filters are created equal. Dual-element air filters, such as are found in Honda engine models such as the Honda GX series, offer benefits that traditional single-element filters simply can’t match.

In this article, we’ll explore the advantages of dual-element air filters and why keeping both elements in good condition is such an important part of Honda engine maintenance. From improved engine power and fuel efficiency to reduced emissions and longer engine life, the benefits of dual-element air filters are clear. So sit back, take a deep breath, and let’s dive into the world of Honda engine air filters!

How Air Filters Work

First, let’s take a quick look at how air filters work in general. As an engine runs, it pulls a constant stream of air to be mixed with the fuel before it enters the combustion chamber to be burned.

The air filter in your engine is designed to remove contaminants from the air before it enters the combustion chamber. If particles of dirt would enter the chamber, they would damage the mirror-smooth finish on the inside of the cylinder, reducing performance and the engine’s ability to burn the fuel efficiently.

Single-element air filters, as the name suggests, have a single layer of filtration material. While they are effective at removing larger particles, they can struggle to capture the smallest particles, which can lead to a decrease in engine performance over time.

Dual-element air filters, on the other hand, have two layers of filtration material, which allows them to capture a wider range of particles. The two layers are separate components and can often be removed or replaced separately. The first filter is like a foam sleeve that slides onto the outside of the cartridge-like second filter. They work together to clean the air in two stages, keeping your engine running at peak performance for longer.

Benefits of Dual-Element Air Filters over Traditional Air Filters

Now that we know how air filters work, let’s take a closer look at the benefits of dual-element air filters over traditional air filters.

Improved Engine Performance and Efficiency

One of the main benefits of dual-element air filters is engine performance. By capturing the maximum amount of dirt particles, dual-element air filters can help keep the air inside your engine cleaner, which results in cleaner burning, less fuel consumption, less air pollution, less internal damage, easier starting, and more power. When your engine is running on clean air, it can perform at its best.

Extended Engine Life and Reduced Maintenance Costs

Another advantage of dual-element air filters is that they can reduce wear and tear on the engine. This in turn reduces the need for costly repairs and extends the life of the engine.

Why You Should Never Operate a Honda Engine with One or Both of the Filter Elements Missing

It’s important to note that dual-element air filters are designed to work with both filter elements in place. If one or both filter elements are missing, your engine may not receive the necessary filtration, causing damage. That’s why it’s important to always make sure both filter elements are in place and in good condition.

Air Filter Cleaning Tips for Honda Dual-Element Air Filters

To keep your dual-element air filter performing at its best, it’s important to clean it regularly. The filter should be checked often to see if it needs to be cleaned, especially when running the engine in dusty conditions. Here are some tips for cleaning your Honda dual-element air filter:

- Remove the air filter from your engine and gently tap it on a hard surface to remove any loose dirt and debris.

- Use compressed air to blow out any remaining dirt and debris.

- If the filter is still dirty, wash it with a mild soap and warm water, then rinse thoroughly and allow it to dry completely.

- Once the filter is dry, apply a light coat of air filter oil to the filter element to help trap dirt and debris.

It’s important to follow these cleaning tips regularly to ensure your dual-element air filter is working at its best.

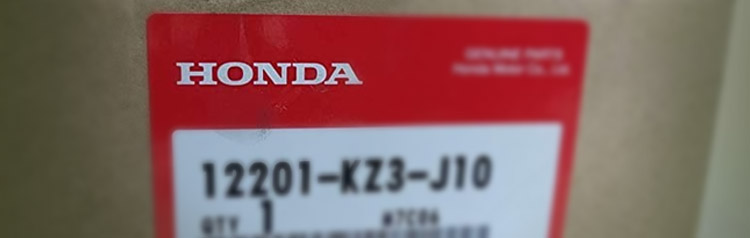

How to Order Air Filters on Hondalawnparts.com

If you’re in need of a new dual-element air filter for your Honda engine, you can easily order one online at hondalawnparts.com. Simply select your engine model to pull up all the parts related to that model. If you know the Honda part number for the filter you need, you can simply search for that number.

Genuine Honda parts are designed to fit your engine perfectly. With fast shipping and competitive pricing, hondalawnparts.com is the perfect place to order all your Honda engine parts and accessories.